This article is part of a series dedicated to exploring food technologies.

Author: Nassab Atwi

Contributing Editor: Samar Yammine

Innovation and business growth are inseparable partners, working hand in hand to drive success. The art of innovating processes, reshaping them to embrace cutting-edge technologies, and ultimately enhancing efficiency, cost-effectiveness, and operational excellence is a strategic imperative. This profound decision often rests upon the shoulders of business owners and CEOs, representing a pivotal crossroads. While larger corporations with established R&D departments might find this journey relatively smoother, foraying into process revamp can be a labyrinthine venture for SMEs. The journey is rife with challenges, from the financial investment required to the daunting nature of change itself.

Envision 3D Printing, Cold Plasma, Ultrasound Technology, and Forward Osmosis; all novel techniques that have emerged as potent solutions to improve preservation methods, bolster food safety, elevate separation techniques, and even redefine the very art of food molding.

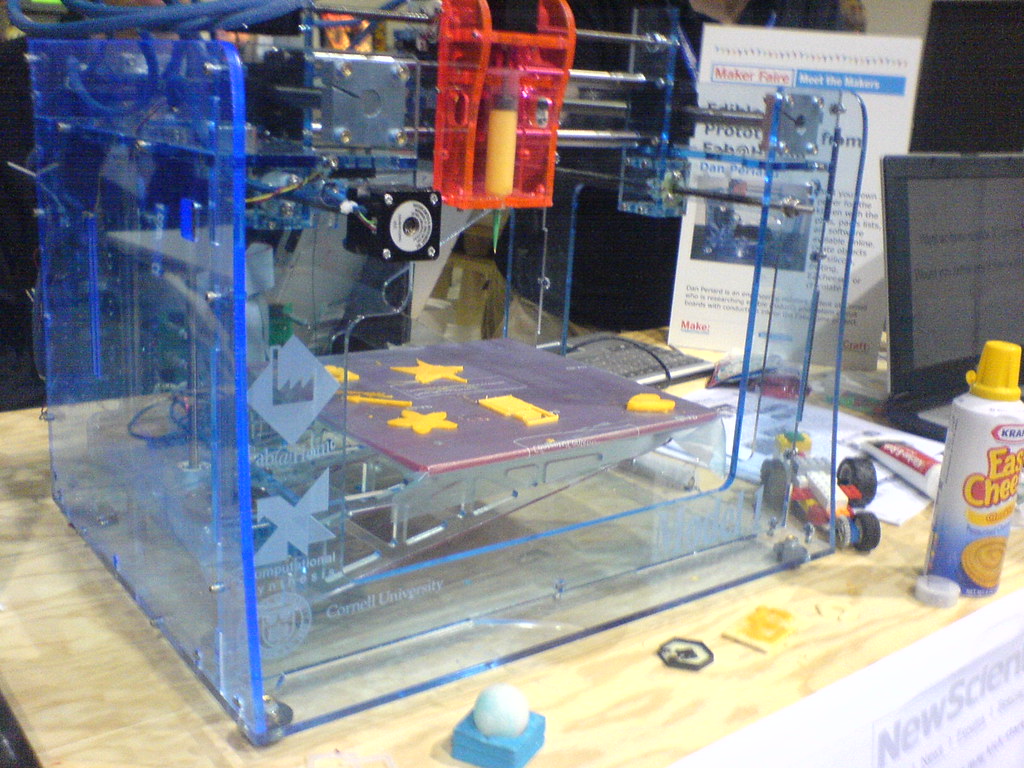

1. Printing a Flavorful Tomorrow: 3D Food Printing’s Appetizing Creations

3D Food Printing is a digitalized process that can revolutionize the way we create and enjoy food. This innovative technology has the potential to transform the food industry by allowing the creation of customized food products with pre-designed shapes and structures. This technology has applications across various sectors, including confectionery, chocolate, and dough-based products, and it offers several exciting possibilities from customization and personalization, to complex geometries, precise ingredient placement, and much more.

Zoom-in On Science:

3D food printing technology, also known as additive manufacturing or rapid prototyping, utilizes digitalized processes such as software or image acquisition hardware, (such as a 3D scanner) to create three-dimensional food structures based on pre-designed shapes (Agunbiade et al., 2022). This technology enables the fabrication of customized food products by layering multiple materials on top of each other without requiring specific tools or human intervention. The range of applications in 3D food printing includes confectionery, chocolate, and dough-based products (Hussain et al., 2021).

2. The Cool Science of Cold Plasma: Transforming Food Preservation and Safety

Cold Plasma Technology is a non-thermal technique operating at room temperature that effectively inactivates foodborne microbes, sterilizes surfaces, and degrades toxins. Discover its versatility in decontaminating meat, poultry, seafood, milk-based products, fruits, and vegetables, and how it paves the way for a safer and healthier food supply.

Zoom-in On Science:

Cold plasma (CP) is a non-thermal technique that operates at room temperature. CP refers to ionized gas that consists of a mixture of excited atoms/molecules, ions, free radicals, reactive species, and others. This composition and reactivity make CP suitable for the inactivation of food microbes, sterilization of food surfaces, and degradation of pesticides and toxins. Cold plasma technique can be used for the decontamination of meat, poultry, seafood, milk-based products, fruits and vegetables, and other products (Punia Bangar et al., 2022).

3. Sonic Waves of Innovation: Ultrasound Technology’s Impact on Food Processing

Ultrasound Technology is a non-thermal method that utilizes high-frequency sound waves to revolutionize food preservation, quality assessment, and analysis. It’s utilized in various food processing steps, such as cutting, drying, and extraction of bioactive compounds. It enhances the production of your favorite foods like cheese and mayonnaise resulting in improved processing efficiency, quality, and consistency. To further explain, Mayonnaise, for instance, is an emulsion of oil and water, and ultrasound can aid in the emulsification process by breaking down oil droplets into smaller sizes, which leads to a more stable and creamy texture.

Zoom-in On Science:

Ultrasound technology is a non-thermal method that refers to the application of high-frequency sound waves ranging from 20 kHz to 100 kHz. This technology offers several beneficial effects in the food industry such as food preservation (dairy products, fruits, and vegetables), food quality assessment, and food analysis (cereal product: texture, density…) (Chavan et al., 2022). It also helps in different food processing steps such as cutting (cheese, bread), drying, ultrasound-assisted freezing (meat and milk products), extraction of bioactive compounds (plant material), emulsification (mayonnaise, dressings) (Bhargava et al., 2021).

4. Embracing Forward Osmosis for Energy-efficient, Sustainable Processing

Forward Osmosis (FO) may sound like a complex term, but the concept is surprisingly simple and offers immense potential for the food industry. FO is an efficient alternative for drying and evaporation methods (separation process). Why should agri-food producers consider FO as an alternative to traditional methods? FO can be used for water desalination, dehydration, and concentration of fruit juices—all at room temperature! This means you can preserve the juice’s natural flavors and essential nutrients without compromising on quality.

Zoom-in on Science:

Forward osmosis (FO) is a method that involves the movement of water molecules from a low solute concentration solution to a higher solute concentration solution through a semi-permeable membrane, driven by osmotic pressure. The process is done by using a draw solution: a solution that has a higher concentration of solutes compared to processed liquid food (Rastogi, 2014). This technique can be used as an alternative to traditional evaporation or drying processes. In the food industry, forward osmosis has several potential applications and benefits such as water desalination, dehydration, and concentration of fruit juices at room temperature without the need for heat which helps in preserving the natural flavors and nutrients of the juice (Haupt & Lerch, 2018).

About the Authors

Nassab Atwi is currently pursuing her graduate studies at the prestigious American University of Beirut (AUB) with a specialization in Food Technology. Armed with a bachelor’s degree in biology from Lebanese University, Nassab’s diverse academic background provides her with a unique perspective when tackling the challenges of food technology. Her cross-disciplinary approach allows her to explore connections between biology and food science, opening new avenues for research.

Samar Yammine is a Senior Program Officer at Berytech and leading the SME Department’s Programmatic Support Unit. She holds a bachelor’s degree in chemical engineering and is pursuing her studies in Energy Management. She is a passionate researcher in the subjects of water, wastewater, and energy management. With solid foundation in engineering principles and problem-solving, her interests expand to processing, innovation, digital marketing, entrepreneurship, and artificial intelligence.

References

Agunbiade, A. O., Song, L., Agunbiade, O. J., Ofoedu, C. E., Chacha, J. S., Duguma, H. T., Hossaini, S. M., Rasaq, W. A., Shorstkii, I., Osuji, C. M., Owuamanam, C. I., Okpala, C. O., Korzeniowska, M., & Guine, R. P. (2022). Potentials of 3d extrusion‐based printing in Resolving Food Processing Challenges: A perspective review. Journal of Food Process Engineering, 45(4). https://doi.org/10.1111/jfpe.13996

Bhargava, N., Mor, R. S., Kumar, K., & Sharanagat, V. S. (2021). Advances in application of ultrasound in Food Processing: A Review. Ultrasonics Sonochemistry, 70, 105293. https://doi.org/10.1016/j.ultsonch.2020.105293

Chavan, P., Sharma, P., Sharma, S. R., Mittal, T. C., & Jaiswal, A. K. (2022). Application of high-intensity ultrasound to improve food processing efficiency: A Review. Foods, 11(1), 122. https://doi.org/10.3390/foods11010122

Haupt, A., & Lerch, A. (2018, July 23). Forward osmosis application in Manufacturing Industries: A short review. Membranes. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6160976/

Hussain, S., Malakar, S., & Arora, V. K. (2021). Extrusion-based 3D food printing: Technological approaches, material characteristics, printing stability, and post-processing. Food Engineering Reviews, 14(1), 100–119. https://doi.org/10.1007/s12393-021-09293-w

Punia Bangar, S., Suri, S., Nayi, P., & Phimolsiripol, Y. (2022). Cold plasma for microbial safety: Principle, mechanism, and factors responsible. Journal of Food Processing and Preservation, 46(12). https://doi.org/10.1111/jfpp.16850

Rastogi, N. K. (2014). Opportunities and challenges in application of forward osmosis in food processing. Critical Reviews in Food Science and Nutrition, 56(2), 266–291. https://doi.org/10.1080/10408398.2012.724734